|

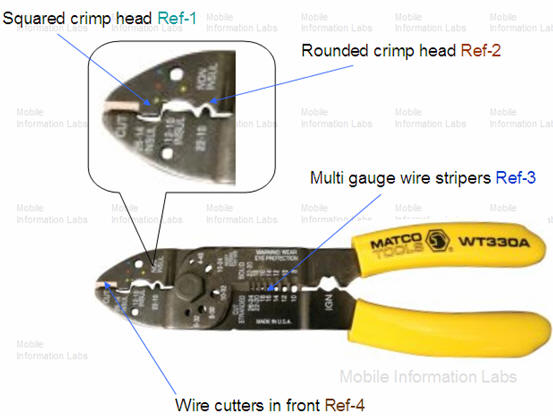

Dissection of the crimper and wire stripers

There are many

different types and styles of crimper/wire stripers on the

market. If you have a cheap pair of crimpers you will get a

cheap install. That simple.

We're not

suggesting that you go out and get a $35-$50 dollars pair of

crimpers, in fact you can pick up a decent pair of

crimpers/wire stripers for about $15 to $20 dollars at your

local home supply store.

We happen to

prefer the type used above. It's not an advertisement for a

company, in fact, it can be any company you desire, as long

as it is a good quality and has a few very important

features we will discuss here:

Ref-1

For the type of

crimping you will be using in most automotive electronics

installation applications, you do NOT want to use the

squared crimp head, as it will give an inferior crimp,

allowing the wire to back out of the terminal and create an

open circuit .

See Ref-1.

Ref-2

For automotive

accessory applications, a round crimp

head will give the maximum hold to the most commonly used

terminals and connectors.

See Ref-2.

Ref-3

A multi gauge - wire

striper located on the crimpers will increase efficiency of

the install, as you only have to manage one tool as opposed

to having a separate striper and separate

crimpers.

-

When

installing any device in a vehicle, you want to have

the least amount of tools in the vehicle at any time.

-

This will

increase the "moving around " space and reduce the

chance of a lost tool.

-

Trust us on

this one when we say that some vehicles have a magical

place where expensive tools simply vanish into thin air

and go visit and live where all your socks and underwear

go! We here at mobile labs like to call it, Sockland, or

(sock-land) not to be confused with Ireland). See Ref-3.

Ref-4

This is an

important one. Your crimper/wire stripers should have a wire

cutter in the very front, not in the middle where the multi-

gauge wire striper is at.

This is important

in many cases where you will not have ample room to access a

wire in the dash by maneuvering the cutters in the middle of

the crimpers.

See Ref-4.

Continue to:

Testing equipment

|